Dorfner offers mineral fillers from the GRANUCOL® family for innovative kitchen designs and durable surfaces. Our solutions enable flexible design, high chemical and mechanical resistance and attractive surfaces.

Mineral-based composites

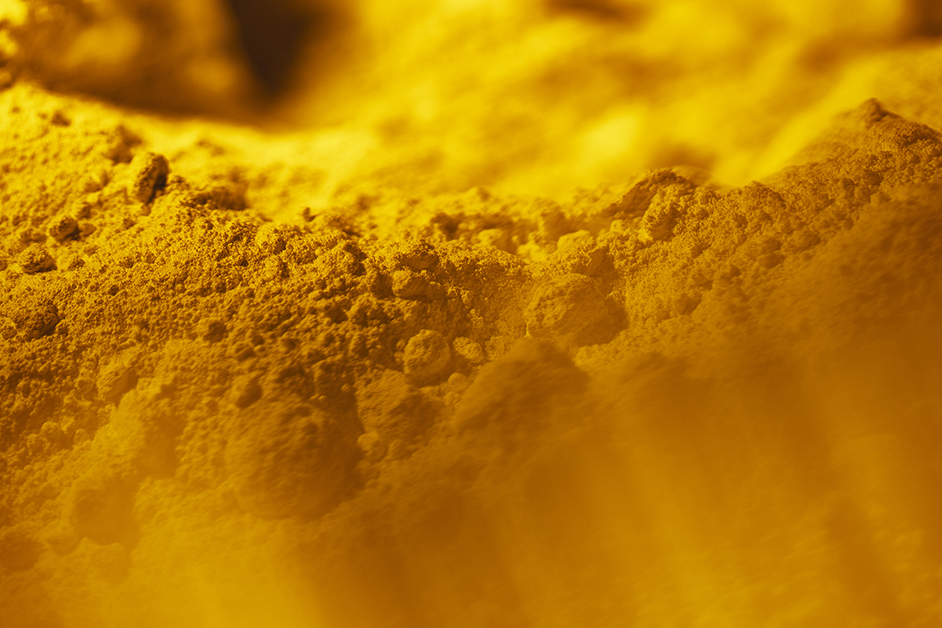

Dorfner’s ultra-fine fillers are the first step towards reinventing the company and its product range, as they allow manufacturers of composite objects to break new ground in terms of design language – without losing sight of economic efficiency.

Functional fillers from Dorfner allow manufacturers of composite objects to break new ground in design language. At the same time, they never lose sight of economic efficiency. Fillers from Dorfner enable aesthetic objects with a manufactured look that can be produced profitably in series with only minor adjustments to the production process.

Regardless of whether the portfolio as a whole is to be raised to a new design level or whether design-oriented series are to be positioned in the upmarket: Dorfner’s fine fillers are the first step towards reinventing yourself and your range.

Mineral-based composites from Dorfner offer a wide range of advantages for all areas:

Outstanding UV stability as well as anti-scratch, anti-stain, anti-crack and anti-blushing properties

Dorfner has been an innovator and development partner for mineral fillers for composite materials from the very beginning. For example, we have made a significant contribution to ensuring that kitchen sinks made of synthetic resin-based quartz composites can be manufactured to a high degree of technical perfection and in an economically efficient manner.

Our fillers must have optimum chemical and physical properties for use in composites. We have therefore surface-treated the surface properties of our high-quality quartz grain – on the one hand to improve the coating of the filler grain, and on the other to better anchor reactive groups on the filler particles. In this way, composites with our GRANUCOL® products achieve greater resistance and more temperature-resistant strength with less binder.

Outstanding UV stability as well as anti-scratch, anti-stain, anti-crack and anti-blushing properties

Dorfner has been an innovator and development partner for mineral fillers for composite materials from the very beginning. For example, we have made a significant contribution to ensuring that kitchen sinks made of synthetic resin-based quartz composites can be manufactured to a high degree of technical perfection and in an economically efficient manner.

Our fillers must have optimum chemical and physical properties for use in composites. We have therefore surface-treated the surface properties of our high-quality quartz grain – on the one hand to improve the coating of the filler grain, and on the other to better anchor reactive groups on the filler particles. In this way, composites with our GRANUCOL® products achieve greater resistance and more temperature-resistant strength with less binder.

Whether it’s consistent quality, multifunctionality or design aspects. The people at Dorfner understand the needs and requirements of the industry. We offer more than just a simple filler, a valuable solution. See for yourself.

Quality begins with the starting product – Dorfner’s pure natural quartz with its unique spaeroid grain shape. In addition, this base leads to top-coated fillers and thus to uniform coloring in the kitchen sink. A convincing combination.

Pure crystal quartz powders, colored fine fillers and renewable product qualities – Dorfner’s filler solutions offer the perfect solution. They open up a wide range of applications, from mineral casting and quartz composite to innovative composite applications.

Mineral-based composites from Dorfner:

Limitless design options.

A pleasant feel and unlimited variety of shapes – from a single source. Composite materials with Dorfner fillers give designers and manufacturers complete freedom.

A pleasant feel and unlimited variety of shapes – from a single source. Composite materials with Dorfner fillers give designers and manufacturers complete freedom.

They meet all producers’ requirements in terms of surface structure and shape as well as weight, color and production flexibility.

Mineral-based composites from Dorfner:

Sustainable filler systems of the future.

Dorfner is a development partner for innovative filler systems that help to make products more sustainable and resource-efficient. As an expert in composite materials, Dorfner invests its extensive know-how in the further development of products and processes for composite materials based on renewable, natural raw materials.

From development to market launch:

We are here for you!

We see ourselves as a development partner for our customers in the field of mineral-based composites and support them with a professional application technology service and our R&D department: from product development through to production.

Casting tests according to individual customer requirements can be carried out on Dorfner’s own equipment, so that new filler solutions can be integrated perfectly and smoothly into the customer’s own processes.

If required, we can also support you with recommendations on machine technology and suitable resins and molds.

If you would like to find out more about Dorfner services for the composites industry and our broad product portfolio, please contact us.

Christian Kerber

Head of Business Unit Composites Solutions

Phone: +49 (0) 151 11167285

E-Mail: christian.kerber@dorfner.com